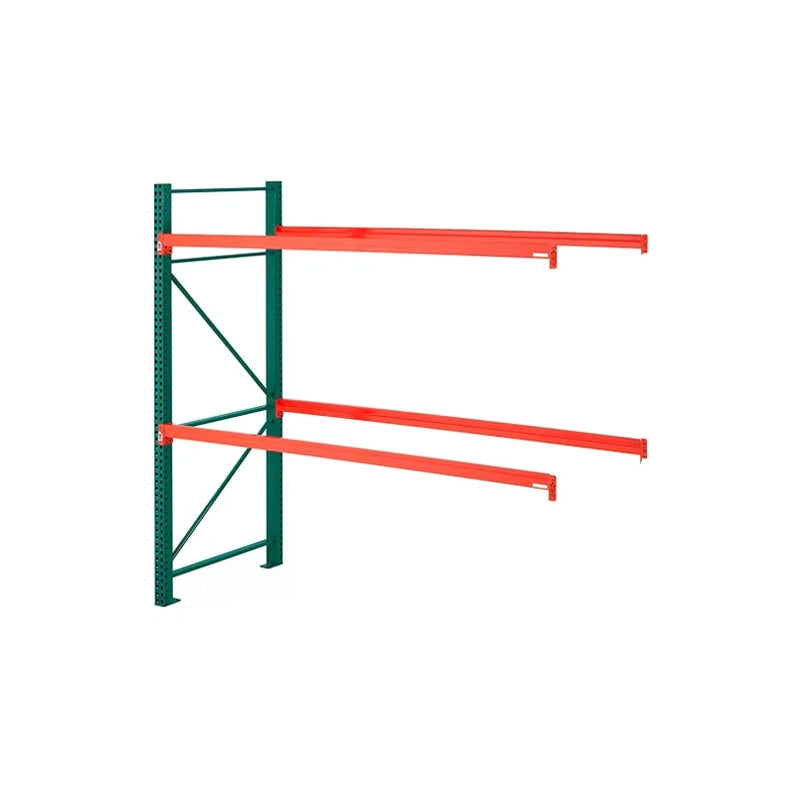

96"W x 36"D x 96"H Teardrop Add-On Pallet Rack Kit | 5080 lb Capacity Per Level

Delivery and Shipping

Delivery and Shipping

Shipping calculated at checkout. All truck and parcel shipments are packaged for safe and efficient delivery of materials; learn more.

This 96"W x 36"D x 96"H teardrop add-on pallet rack kit is USA-made and features a closed-tube construction for longer lasting and safer operation with a total capacity* up to 22,780 lb and individual level capacity to 5080 lb. This SK2000 bay add-on kit includes the necessary upright frame (qty. 1; item# RTFAP036096F01VG) and beams (qty. 4; item# SBRUM400096P) to add an additional racking bay to our corresponding starter kit (sold separately and displayed in Add-on Products on this page). If you are not providing your own concrete floor anchors, you can purchase them separately here. Optionally, join more add-on bays to continue creating a longer aisle of racking or purchase additional SK2000 beams to increase the storage levels within your bays. The strength of our SK2000 closed-back upright frames make our rack significantly safer and more functional than open-back rack. Independent engineering tests have confirmed that, when compared to open-back column, SK2000 pallet racking has:

- 250% more front impact strength

- 44 times more twist resistance

- 68% more side impact resistance

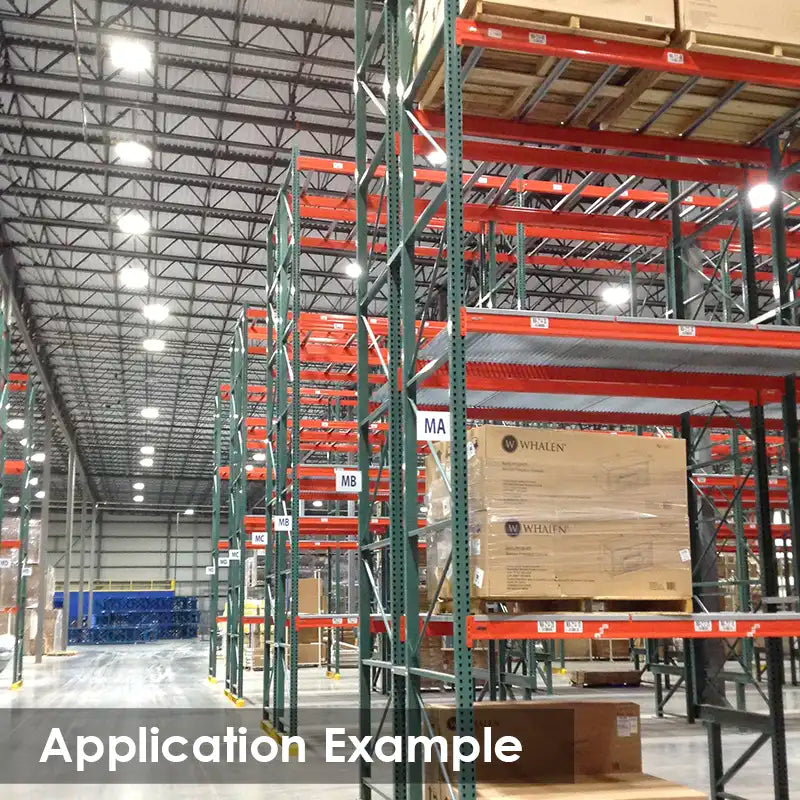

These safety factors make this strong, yet lightweight, boltless tubular rack a popular choice for selective rack, gravity flow, pushback and pick module applications. SK2000's columns and beams are formed from high-strength American-made steel, continuously welded into closed-back sections, providing exceptional strength and dramatically increased durability compared to other products on the market. Its boltless design, with auto-engaging safety locks (prevents accidental beam disengagement per RMI specifications) and teardrop connections, makes it easy to install without tools, which can lead to faster install times and less expensive installation. If you need support in selecting, designing a complete rack structure, or locating an installer, we are here to help–just chat or contact us now.

Upright frame bracing is secured with full fillet weld that is 4 times more weld than many competitors’ racks. Beams feature a 3-rivet connection that easily inserts into frame teardrops and is 26% stronger than competitive 2-rivet designs. Beams can easily be adjusted in 2" vertical increments on frame and have a 1-5/8" step for optional wire decking and pallet supports (sold separately). When it comes to a highly versatile and effective rack solution that will provide lasting safety and storage, this is your rack. An appealing powder coat in our Vista Green (frames) and Poppy Orange (beams) color not only makes the racking appealing but it also more durable against damage, and more resistant to chemicals and scratches compared to liquid paint coatings.

-

Series

-

Size Summary

-

Capacity*

-

Connection Type

-

Width (in.)

-

Depth (in.)

-

Height (in.)

-

Finish Method

-

Color

-

Material

-

Construction

-

Compliance

-

Beam Adjustment

- SK2000 Assembly Manual

- Pallet Rack User & Safety Manual

- SK2000 Product Brochure

- SK2000 Capacity Charts

- SK2000 Test Report Frontal Resistance

- SK2000 Test Report Horizontal Braces

- Warranty

*Notes to Upright Capacities:

- Capacity is based on 36" vertical beam spacing; larger spacing will decrease capacity.

- Capacities based upon interior usage.

- Capacities are for selective rack only.

- Capacities are for non-seismic usage; contact us for seismic requirements.

- All columns and posts must be properly anchored (anchors sold separately) to an adequate concrete floor (required by RMI code)

- Capacities based upon plumb and proper installation.

- Capacities are total per upright, assuming equal loading on both posts.

- For any outdoor storage, stainless steel anchors are required.

If any of these conditions do not apply to your application, or you are unsure, do not use these capacities and consult our engineering department to ensure proper specification and application requirements are met. A permit and/or stamped calculations may also be required by your local building department prior to installation and is the responsibility of the end user. Contact us for any seismic location requirements prior to ordering.

Payment & Security

Payment methods

Your payment information is processed securely. We do not store credit card details nor have access to your credit card information.