For manufacturers, distributors, and retailers

Types of Pallet & Storage Racks

Utilizing the right types of racking for your operations will deliver lasting efficiencies and safety for your people, inventory, and building.

Selective Pallet Racking

Selective pallet racking is the most widely used racking system, providing direct access to each pallet from the front of the rack. This system is highly versatile and can accommodate a wide variety of pallet sizes and weights. Utilizing either teardrop or bolted beam connections, it is flexible for inventory management and is ideal for businesses with a large variety of products. The ability to quickly access any pallet makes it perfect for warehouses with fast-moving items and high SKU counts.

Drive-In / Through Racking

Drive-in and drive-through racking systems are designed to maximize storage density by minimizing aisle space. In drive-in racking, forklifts enter from one side to pick up or deposit loads, while drive through racking allows entry from both sides. These systems are best for storing large quantities of homogenous products. By optimizing space, they are ideal for high-density storage needs, such as in cold storage warehouses where space is at a premium.

Over Dock Door Racking

Over dock door racking is a storage solution that utilizes the space above dock doors, which is often underutilized in warehouses. This racking system is designed to store pallets or other inventory items directly above loading docks, freeing up valuable floor space for other operations. It helps maximize storage capacity without expanding the warehouse footprint, making it an efficient solution for warehouses with limited space. Over dock door racking is perfect for staging outbound shipments, organizing seasonal inventory, or storing items that need to be readily accessible for shipping and receiving.

Push-Back Racking

Push-back racking uses a system of nested carts that move along inclined rails. When a new pallet is loaded, it pushes the existing pallets back. This high-density storage system allows multiple pallets to be stored deep and accessed from the same aisle. It offers efficient use of space and is particularly useful for warehouses needing high selectivity and storage density. Push-back racking is excellent for managing a large volume of similar items while maintaining relatively easy access.

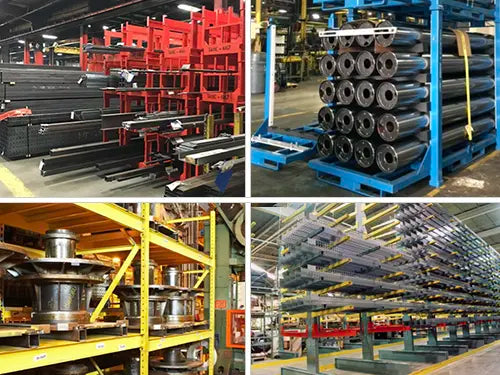

Cantilever Racking

Cantilever racking is specifically designed to store long, bulky items such as lumber, pipes, or steel bars. It features horizontal arms that extend from a central column, providing unobstructed access without front columns. This design allows for flexible storage of varying lengths and shapes, making it easy to load and unload items. Cantilever racking is highly adaptable and can be customized to different heights and weight capacities, ensuring efficient use of vertical space and improved organization of non-standard items.

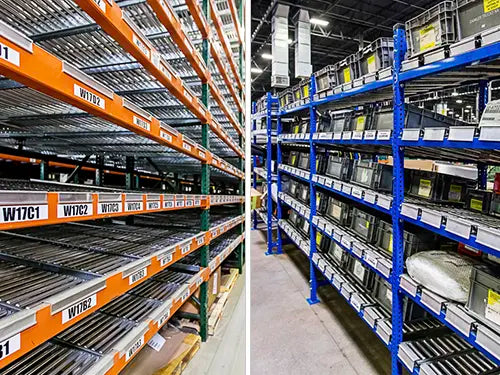

Pallet Flow Racking

Pallet flow racking, also known as gravity flow racking, utilizes inclined rails equipped with rollers, allowing pallets to move forward from the loading end to the picking end under the force of gravity. This system is ideal for first-in, first-out (FIFO) inventory management, ensuring optimal product rotation and reducing the handling times. It's especially beneficial for perishable goods or items with expiration dates. Pallet flow racking maximizes storage efficiency and space utilization by creating a continuous flow of products, enhancing accessibility and throughput in high-volume operations.

Carton Flow-Cell Racks

Carton flow-cell racks operate similarly to pallet flow racking but are designed for smaller items stored in cartons or bins. Racks feature inclined shelves with roller or wheel tracks, enabling cartons to glide smoothly to the front for easy picking. They can be installed in existing pallet racking with use of Span-Tracks or as standalone racks that feed production lines or assembly work-centers. This system can support first-in, first-out (FIFO) inventory management and is highly efficient for order picking, improving productivity and reducing picking times. Carton flow-cell racks are ideal for high-volume picking environments such as e-commerce, pharmaceuticals, and retail distribution centers, where quick access to a wide variety of items is crucial.

Pick Module Racking

Pick module racking systems are multi-level structures designed to streamline the picking process in high-volume order fulfillment environments. These systems integrate various types of racking, conveyors, and storage solutions to create a highly efficient picking operation. Pick modules can include carton flow racks, pallet flow racks, and shelving to support different product types and picking methods. By optimizing space and improving order picking speed and accuracy, pick module racking enhances overall warehouse efficiency. They are ideal for e-commerce, retail distribution centers, and any operation requiring fast and accurate order fulfillment.

Specialty & Bulk Material Rack

For unique storage requirements, space-savings, and mobility, we design racks custom to your needs. From heavy and large die storage racks to bulk material racks that can be transported throughout your facility or manufacturing process, we are ready to tackle your unique racking needs to ensure your facility, people, and materials stay as safe and efficient as possible.

Retail Storage Speed-Cell

The Speed-Cell storage product is an innovative dynamic storage solution designed to maximize space efficiency and improve organization in retail environments. This system utilizes a series of high-density storage columns composed of flexible, durable material that creates individual cells for storing items. Speed-Cell can be easily configured to fit a variety of product shapes and sizes, making it perfect for backroom storage, stockrooms, and any area where space is at a premium. By significantly increasing storage capacity within a smaller footprint, Speed-Cell enhances accessibility and inventory management, leading to quicker restocking and improved operational efficiency. Its modular and flexible design allows for easy installation and reconfiguration, adapting to changing inventory needs and providing a streamlined, cost-effective storage solution.

Ready to discuss a project?

We're ready to design the perfect solution.