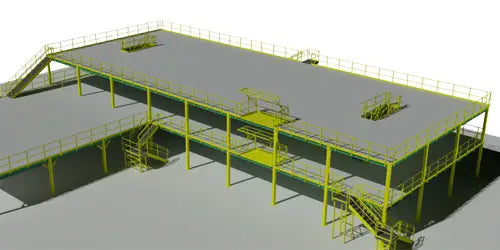

Engineered Mezzanines

Effectively increase usable storage space without expanding the building's footprint. Our engineers are ready to show you the possibilities.

How Mezzanines and Pallet Racking Work Together

Mezzanines and pallet racking systems can work together to significantly enhance warehouse operations by maximizing vertical space and improving overall storage efficiency. By integrating mezzanines, which are elevated platforms between the floor and ceiling, with pallet racking systems, warehouses can create additional storage levels above existing floor space, effectively doubling or even tripling usable space without expanding the building's footprint. This multi-level approach allows for the separation of different types of storage and operations, such as placing bulk storage on the mezzanine and using the ground level for more frequently accessed items. The combination of these systems facilitates better organization, streamlined workflows, and quicker access to inventory, ultimately boosting productivity and operational efficiency.

Key Considerations for a New Mezzanine Storage Project

When planning a new mezzanine storage project, one of the primary considerations is the structural integrity and load capacity of both the mezzanine and the supporting building. Ensure that the mezzanine is designed to handle the weight of the stored materials, equipment, and personnel, and that the building's structure can support the additional load. Safety regulations and compliance with local building codes are critical; this includes incorporating features such as guardrails, staircases, and appropriate lighting to ensure a safe working environment.

Another key consideration is the layout and integration with existing warehouse operations. The design should optimize workflow efficiency, with strategically placed access points and consideration for material handling equipment such as forklifts and conveyors. Adequate aisle width and clearances should be maintained to ensure smooth movement of goods and personnel. Additionally, future scalability should be factored into the design to accommodate potential growth or changes in inventory needs. Lastly, consider the total cost of the project, including initial construction, ongoing maintenance, and potential future expansions, to ensure it aligns with the operational and financial goals of the business.

Want to discuss a project?

We are ready to design the best solution.